Trumpf invests €70M in EUV laser building

source:optics.org

release:Johnny

keywords: TRUMPF CO2 lasers EUV lithography

Time:2015-06-18

Industrial laser firm Trumpf is to invest €70 million in a new building wher engineers will make ultra-high-power lasers for the emerging generation of extreme ultraviolet (EUV) lithography equipment needed by semiconductor chip manufacturers.

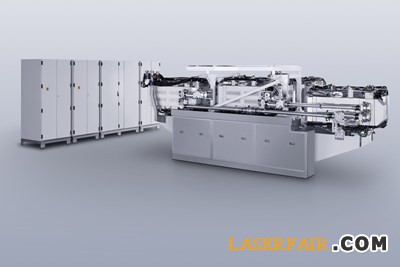

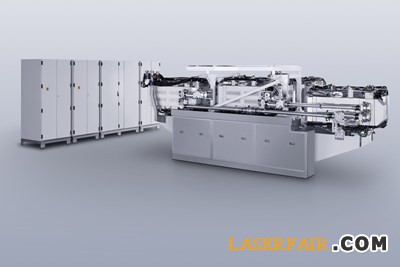

Power play: Trumpf's EUV-generating laser

The lasers play a key role for generating EUV light in the source of those lithography tools, which are in the final stages of development by ASML. The EUV light, with a wavelength of 13.5 nm, is created when a pulse from a powerful carbon dioxide laser vaporizes a train of tin droplets – with a solid-state laser also used as a “pre-pulse” to improve efficiency.

Power play: Trumpf's EUV-generating laser

The commercial deployment of the highly complex and expensive systems has been hit by years of delays and met a great deal of skepticism along the way. However, ASML announced a 15-system order in April that appeared to confirm EUV’s viability, and the Dutch firm’s most recent predictions suggest that it will deploy 12 of the tools next year, followed by 24 in 2017, and another 48 in 2018 as the technology becomes more widely used to advance Moore’s law by shrinking feature sizes to less than 10 nm – smaller than a virus.

Trumpf says that building the new 34,000 square meter site will take around two years, after which its dedicated Lasersystems for Semiconductor Manufacturing subsidiary will start producing giant amplifiers that will feature four powerful lasers connected in series.

“We're developing and producing unique and highly complex laser systems here, and this is creating high-tech jobs in Germany,” said Trumpf’s president Nicola Leibinger-Kammüller. The €70 million investment is said to include both the costs of construction as well as setting up some elaborate building automation features that are required by the ultra-clean demands of the semiconductor industry.

The multi-storey site will include production zones, clean rooms and areas for equipment testing, while there will be space for 270 jobs in an adjacent office block.

“High-tech clay pigeon shooting”

The complexities of EUV source generation are made clear in Trumpf’s most recent annual report, in which the company states that a pulse repetition rate of 50,000 Hz is needed – along with peak powers exceeding a megawatt – to fire at a stream of tin droplets.

Each of those droplets has to be hit by the laser with extreme precision, to ensure that the EUV source power is sufficiently stable to meet the exacting requirements of ASML’s chip-manufacturing customers – the likes of Intel, Samsung and the Taiwan Semiconductor Manufacturing Company (TSMC) foundry. The German firm likens that challenge to “high-tech clay pigeon shooting”.

It also describes how several 16 kilowatt CO2 lasers are switched in series to achieve the required power levels and ultimately generate around 100 Watts of EUV output from the source plasma.

The high-tech but hugely inefficient process of generating that light has been likened by others in the past to “using a nuclear reactor to power a village” – but has also emerged as the only viable way to scale EUV power output to meet the throughput requirements of the semiconductor industry.

With Trumpf among the only companies able to deliver lasers capable of supporting EUV, the business promises to be a lucrative one for the Ditzingen firm if it does take off in the way that ASML has predicted.

For its most recent financial year, 2013-2014, Trumpf said that the EUV application already accounted for “far above” 10 per cent of the €841 million sales registered by its laser technology division.

One particular challenge for Trumpf in this regard has been the round-the-clock service model required by the chip makers. As a result, service specialists for EUV laser systems from Europe, Asia and the US have been collaborating since the middle of 2014 to provide a standby service.

“This is the first time that Trumpf subsidiaries from several continents have worked together closely in this way,” noted the firm in its annual report last year.

MOST READ

- RoboSense is to Produce the First Chinese Multi-beam LiDAR

- China is to Accelerate the Development of Laser Hardening Application

- Han’s Laser Buys Canadian Fiber Specialist CorActive

- SPI Lasers continues it expansion in China, appointing a dedicated Sales Director

- Laser Coating Removal Robot for Aircraft

PRODUCTS

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays

New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays A new industrial compression module by Amplitude

A new industrial compression module by Amplitude Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of

Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>

Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>